FAQs

1. Who are you and where are you from?

1. Who are you and where are you from?

My name is Andy, the founder of Wheel Angel. We specialised in wheel building with a wide range of selection and offer a wide range of custom carbon wheelsets, components, accessories and services for Brompton, Birdy and other foldies. Additionally we are beginning to offer wheel building and maintenance courses.

2. What makes your wheels special?

We choose the best components we think that attributes to a pair of performance wheels. At the same time, we want to continue to make them affordable without bursting your wallet.

Customisation, serviceability, workmanship, high stiffness, ultra-smooth rolling and affordability - these are some of the demands our wheels has to meet. A mediocre bicycle frame can still perform fairly well with a good set of wheels while an expensive frame will perform poorly with inferior wheels. So in our opinion, the wheelset is one of the most or otherwise the most important component in a bicycle.

Rims: We offer a few series of rims, namely the Enves, the UCI approved SL28 / SL30 Disc and the innovative Venn rims with unique construction methods. They meet our high expectations as a wheel builder that demands competitive weight, lateral trueness, radial roundness and the ability to accept high spoke tensions without buckling. We can attest to the rims’ qualities when we keep the tolerances of our wheels within 0.2mm laterally and 0.4mm radially under the load of high spoke tensions.

Hubs: What we prefer in a pair of hubs are stiffness, durability, rolling smoothness, serviceability and of course bling factor. Many light-weight hubs use inadequate small bearings to achieve light weight figures, while our choice of hubs we prefered are designed with high loading capacity bearings and patented drive systems with a series of different colour finishes to achieve the big 5s we mentioned above. It annoy us very much when many wheel companies continue to tout consumers with the idea that being lighter is better. No it's won’t help you in your quest for better wheels or even worse, make your ride suffers and your pockets burn.

Spokes: Spokes are the linkages between the rims, the hubs and part of it acts like a suspension system between them. They come in varying cross section diameters and different profiles like bladed or round. Choosing the right spokes for the application is very important. For instance, we do not need spokes that are meant for tandem wheels to be used on road bikes and vice versa. We use the popular forged bladed Sapim CX Ray for most of our road wheels as they are light, aero and easy to work with. Most importantly, they create a stiff and responsive wheel set as the outcome.

Workmanship: Even with all the right components the final important step is proper workmanship when assembling and building the components. We begin by preparing the parts for the building process. Part of this also ensures that the nipples doesn't seize with the rim and spokes during the stage when the spokes are under high tension load. Once the wheel is built completely, we high-stressed the spokes to be properly bedded into the rims and the hubs. And repeat the entire trueing and tensioning process. So when you begin to ride the wheels, you won’t face problems of the wheels going out of true shortly. That being said, we true our wheels to tolerances of 0.2mm laterally and 0.4mm radially with a 95% consistent spoke tension. A good and solid workmanship will ensure that the wheels’ integrity remains virtually intact even when it undergoes a high impact such as an event of an accident, thus assuring your safety further.

3. Do you ship to my country?

Yes. Talk to us to find out more.

4. What are your payment methods?

You may choose to check out via Paypal or Credit Cards.

Or also contact us directly for a wire transfer option.

5. After ordering and paying in your website, how long do I have to wait before I receive my wheels?

We try our very best to keep as much inventories as we can, although it can be really challenging. If the parts are in stock, we will build your wheels fairly quickly. Otherwise the lead time would depend on what components are lacking. You may drop us a message to find out more.

6. I want to order from you but I can't seem to find the specs I need.

As we can't list a full range of our services at the moment, please contact us directly to see what we can do for you. Should you feel that the wheels do not meet your requirements because you are a massive guy or you think you want certain colours to match your bike or your mood, do let us know. We will do our best to help you.

7. Why are custom builds better than off-the-shelf wheels?

We tailor wheels to your needs be it in accordance to your riding preferences, your choice of colour or your weight. We meticulously tune every spoke and nipple to perfection. Usually, off-the-shelf wheels are mass produced with lesser attention given to such details.

Most importantly we want to assure you that you will be getting more for what you pay - in terms of service and quality.

8. I am stuck between a deeper rim profile vs a lighter pair of rims, can you help me with my choice?

This is a question that has no definite answer because every rider is different.

Deeper profiles offer significant aerodynamic benefits that would save you precious watts at higher speeds while shallower profiles and lighter rims allow for easier climbing and handle better in crosswinds.

9. I weigh over 100kg (220lbs), can you suggest a pair of wheels for me?

We have built many wheelsets in the past for heavier riders. Please contact us directly, we will advise and build something suitable for you.

10. How do I take care of my wheels?

The proper method to clean your bike and its components, is to wipe rather than wash. Do not apply degreaser directly at the mounted cassette on your rear wheel or any part of your wheel. Degreaser or chemical cleaners are harmful to the hub and it's component. To know more, email us at askme@wheelangel.com.

11. To prevent the wheels from going out of true, do you use strong loctite or adhesive on your spoke threads against the nipples?

No, that is a very low-handed method in our opinion. To maintain the trueness of the wheel, we build our wheels to proper tensions and use special compounds to prevent seizing of the spokes and nipples. In addition, we "break-in" the spokes & nipples' seating on the hubs and rims to ensure that they are properly bedded in.

Eventually, every good wheel will go a little out of true after extensive usage. Using strong adhesive will impede the mechanic's ease in carrying out maintenance. Spokes and nipples of some brands seize so badly that the spokes get twisted as we wind the nipples.

12. Ceramic bearings; what is your opinion?

Ceramic bearings in bicycles are expensive and highly overrated. If you can (can or can't?) find cheaper ceramic bearings, you are better off saving that money. There are many articles online to explain the redundancy of using ceramic bearings and we shall not go into details here.

Ceramic bearings play a minuscule role in contributing to smooth-rolling hubs and wheels (we doubt it's even 5%).

Bearing drag and resistance are more likely to be caused by its seals, amount & type of grease used as well as the load rating which is highly dependable on the size.

The better solution is proper engineering. A properly drive mechanism design and the use of bigger and adequately-sized bearings in a proper position contributes more to the smoothness of rolling. This may come with a slight weight penalty, but the difference is only about 50 to 100 odd grams (Think if carrying 1 or 2 chocolate bars can slow you down). Many brands use inadequately sized bearings so they can tout the lightness of their wheels. This is highly misleading. Durability depends heavily on thickness of material, and what you get for the tiny 100 grams of extra weight is more than made up for by the increased life & performance of the product. With the inadequately bearing sizes found commonly in many popular wheels, you may find that they may not last as long as they should.

13. Are some of your rims from the Far East?

We are aware of many OEM carbon rims sellers in the market. However, not all wheels you've seen online are as safe, durable and of high quality as ours. At Wheel Angel we have bought, sold and tested hundreds of pairs of rims from the same carbon manufacturer (not any individual re-seller) to ensure the safety of our wheel users, each wheel is then hand-built by us to ensure the highest quality and durability afforded. Additionally, the SL rims have also been certified with the UCI for greater assurance. We have also established great communications and contact with our carbon rim maker. Therefore, we are confident that our wheels are reasonably priced for quality and that we will be able to provide adequate after-sales services should there be a cause for warranty claims. Lastly, being a bespoke wheel builder, we will definitely be able to give you the attention required to build you the perfect wheel.

14. I have a pair of used rims / hubs, can I send them to you to be re-laced with some of your components?

It depends on several factors. We won't do it if your parts are too worn.

As some parts may be proprietary we might not be able to source the replacements easily.

Other than that, we will do our best but we cannot guarantee anything that is built with used parts. Please contact me so that we may discuss this in greater details.

15. Do I have to use the specific brake pads that come with your carbon rims?

Yes and please do that at least for the warranty period for the rims.

The brake pads are specifically designed to be used with the rims. You may consult our opinion should you need to use other brake pads

16. How to keep the hub bearings from going more miles?

Our hubs use high quality bearings and with proper care they will last for many years. We recommend maintenance of your equipment by wiping rather than hosing with water.

Do not use degreaser over the cogset while it's still mounted on the freehub. Get yourself a cassette opener and soak the cogs in a degreaser instead. To know more, askme@wheelangel.com.

17. Are proper spoke tensions important? Why?

Of course they are important. A wheel can be fairly true radially and laterally even without consistent spoke tensions, which means one or more spokes could be subjected to more load than others. This often results in breakages in the lower-tension spokes as they tend to vibrate with more movements leading to material fatigue. A wheel with consistent spoke tensions has all the load and stiffness equally distributed throughout the wheel. Lastly, one can imagine riding a wheel with varying stiffness without proper and equal spoke tensions.

All our tension meters are calibrated in house regularly to ensure correct and adequate readings during the building process.

18. Some say no to alloy nipples and recommend brass nipples. Tell me more.

Unlike brass, aluminium alloys will oxidise, corrode and break with prolonged usage. The Sapim Polyax Alloy Nipple swe use are double colour anodised so the surface has an extra layer of protection against oxidation. We also recommend you clean and maintain the nipples of your wheels (or rather the whole wheel) from time to time regardless of the materials you have chosen.

The weight difference between a set of brass nipples vs a set of alloy nipples on a 20/24 build is less than 30g.

19. What are the Min / Max Tyre pressures allowed on your carbon clinchers rims?

Tyre pressure is relative to your own body weight, tyre width & road conditions.

We suggest not to exceed the maximum pressure of 125 psi for road tyre width of 23 c to 28 c.

20. The more expensive hubs and rims perform better?

Not true. The varying prices of different hubs & wheels are due to its cost when we bought them. Some brands / components are priced higher perhaps due to their manufacturing cost, brands and popularity.

21. Among the hubs you are selling, which one is better?

In the current series of hubs we offer, there isn't a single brand that absolutely stood out over the other. The White Industries, Chris King, Onyx and Velotechnic each has their own merits and features.

White Industries - To date, these hubs are still the podium winners in terms of buttery smoothness with extremely high strength and stiffness. These attributes are largely achieved by their in-house engineering and the use of adequate bearing sizes to provide the highest static load capacity. This directly translate to the bearings' ability to perform and function under heavy load and stresses. In contrast many brands that use much smaller bearings to achieve a light weight totally miss this point.

White Industries hubs are designed with a Titanium freehub body and a steel axle at its rear hub; something that only a very small handful of hub manufacturers do. To sweeten this offer, all White Industries hubs purchase from Wheel Angel are upgraded to 48 points engagement from its original 24.

www.whiteind.com

Chris King R45 's commitment to quality and design can be seen from many perspectives. Firstly, they do not replicate any current hub designs or technology out there in the market. Not even its bearings. Chris King chooses to design and manufacture their own bearings with a unique seal system of unique sizes and dimensions. This enormous effort and investment pays off which result in the long life span, great smoothness as well as ease of serviceability for their bearings.

Many of us are familiar with the sound of Chris King hubs while free wheeling; known as the Chris King Buzz which has attracted many riders to want them. This unique buzz comes as a result from their patent RingDrive™ system with 45 engagement points yet its reactivity is almost instantaneous. Aesthetically the anodised chrome & matte finish on their hub shells are one of their greatest attraction which again sets them apart from their competitors. Every once in a while, Chris King favour new and limited edition colours.

Onyx Road Hubs hits the market like a storm when they introduce the SPRAG CLUTCH system found in their hubs. With the Onyx, they gives you a whole new perspective of riding a bicycle. This system favours the Ironmans, epic distances riders or anyone who wants to ride as quiet as a mouse. The sprag clutch systems are originally designed for machines like large mining conveyors belts & roller coasters because it allows smooth travel in one direction whereas it locks instantly in the opposite. By incorporating this concept and technology for a hub design, the Onyx hubs enables smooth and silence travel when the bike is coasting and gives 100% instant engagement as soon as you crank down. It gives meaning to the phrase, "Riding like a dream" .

Velotechnic is our in house-brand and the DS series hubs are designed and built with the attributes of Strength, Stiffness, Stability & Smoothness to give the best riding experiences while remaining affordable. Designed & engineered in Singapore and manufactured with our own exclusive molds in Taiwan.

The purpose of creating this hub is to capture all the positive attributes of a hub that will not flex at the axle or cantilever between the freehub & hubshell. It is also the hubs achieving one of the lowest drag in the world with it's unique magnetic pawls.

22. What good are the SL Carbon Rims Series?

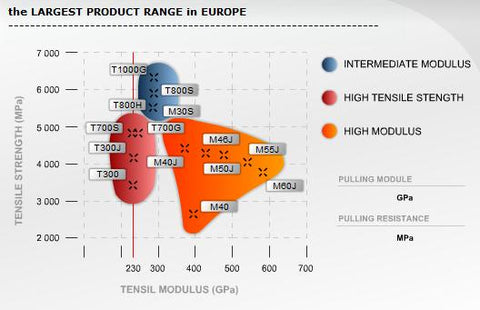

SL Carbon Rims Series are Wheel Angel's in-house rims and they were introduced into the list of UCI Approved Wheels 2016. Made from unbroken continuous layers of T700/800 Toray Carbon Fibre, it boosts of higher tensile strength and tensile modulus yet achieving an overall lighter weight. Comparatively, most carbon rims are made by overlaying cut-pieces of carbon fibres with around 6 segments in a single hoop. The segmented lines can clearly be seen on some of these rims.

The SL Carbon Rim Series also featured clean interiors without any bladder or resin residues from the molding process – showing very clearly the detailed workmanship that goes into every rim. This important aspect not only omit unwanted weight, it also improves the quality of the build as any residues remaining on the nipple bed can affect the build quality.

Finally the (rim) braking feature in SL use high TG resin with its own unique technology. The enhanced strength in the braking walls of the rim ensures that no clincher tyre will dislodge from the bead hook under the worst braking circumstances; like severe overheating leading to sudden punctures on a continuous descent. This is paramount for safety.

The SL Carbon Rim Series still tops as our favourite rims as they have seen podiums & PBs by many elite triathletes and ironmans.

Source: http://www.toray-intl.co.uk/products/carbon-fibre/fibre.aspx